WCMS invests in the latest machinery

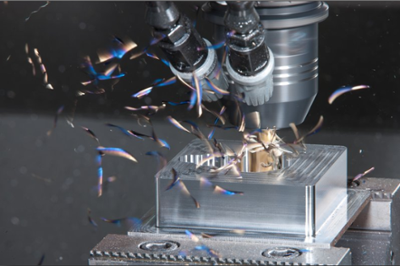

Okuma GENOS M560-V The Okuma GENOS M560-V is highly rigid has thermally stable construction that allows this vertical machining center to withstand thermal deformation. This results in reduced thermal growth and improved machining performance. It can handle a variety of materials, from titanium to aluminum, and does so without sacrificing finish quality or productivity. Designed on the Thermo-Friendly Concept and controlled by the open-architecture, user-friendly OSP-P control, our GENOS M560-V truly delivers affordable excellence. Click here to see our full range of machines: Machine Capabilities A HIGH COLUMN DESIGN, CAT 40 SPINDLE AND INTELLIGENT TECHNOLOGIES ENHANCE THIS CNC MACHINE’S ABILITY TO CUT A VARIETY OF EXOTIC METALS.The new GENOS M560-V vertical machining center, combines a new high column design and CAT 40 BIG- PLUS® spindle to cut large, complex…